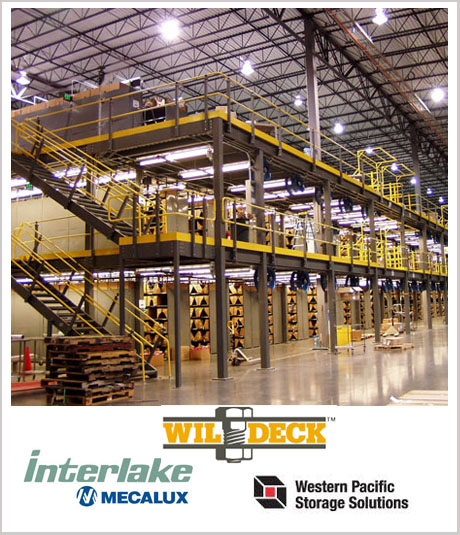

Pick Modules

Ever-increasing SKUs, limited space and tougher than ever order processing requirements; a common and stressful combination of pressures plaguing many distribution centers. If your facility is one of them, a multi-level pick module may be just what you need to fully optimize your storage space and increase picking and order fulfillment efficiency.

Ever-increasing SKUs, limited space and tougher than ever order processing requirements; a common and stressful combination of pressures plaguing many distribution centers. If your facility is one of them, a multi-level pick module may be just what you need to fully optimize your storage space and increase picking and order fulfillment efficiency.

Usually implemented in high volume/high throughput environments, the experienced team at Morrison Company will design a custom pick module for your specific order throughput needs. We analyze your floor space, picking technology, future growth plans and more to plan out your pick module components. Selective pallet rack (with or without decks), steel shelving, push-back, gravity flow (carton and/or pallet), and other storage methods as well as conveyors may be utilized to optimize product flow.

Benefits of Morrison Company Designed Pick Module

- Increase throughput

- Decrease labor cost

- Maximized floor space

- Increase possible number of SKU’s

- Ideal for expiration date sensitive products

- Durable construction for years of maintenance free operation

Morrison Company is recognized as a top producing material handling distributor for Interlake Mecalux, Western Pacific and Wildeck in the U.S.